Notifications

ALL BUSINESS

COMIDA

DIRECTORIES

ENTERTAINMENT

FINER THINGS

HEALTH

MARKETPLACE

MEMBER's ONLY

MONEY MATTER$

MOTIVATIONAL

NEWS & WEATHER

TECHNOLOGIA

TV NETWORKS

VIDEOS

VOTE USA 2026/2028

INVESTOR RELATIONS

DEV FOR 2025 / 2026

ALL BUSINESS

COMIDA

DIRECTORIES

ENTERTAINMENT

FINER THINGS

HEALTH

MARKETPLACE

MEMBER's ONLY

MONEY MATTER$

MOTIVATIONAL

NEWS & WEATHER

TECHNOLOGIA

TV NETWORKS

VIDEOS

VOTE USA 2026/2028

INVESTOR RELATIONS

DEV FOR 2025 / 2026

High Temperature Concept -

8 hours ago -

Technology -

CFC Fixtures and Racks

-

38 views -

0 Comments -

0 Likes -

0 Reviews

High Temperature Concept -

8 hours ago -

Technology -

CFC Fixtures and Racks

-

38 views -

0 Comments -

0 Likes -

0 Reviews

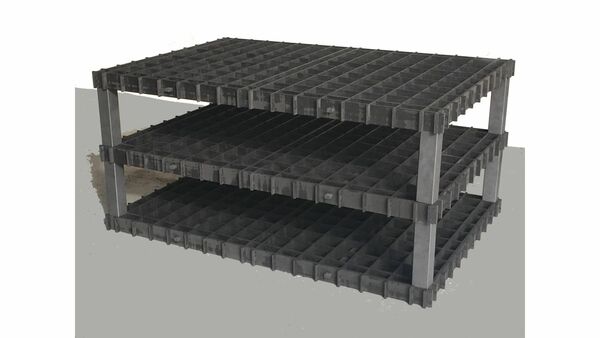

Heat treatment processes, especially in high-temperature applications, require reliable, durable, and efficient equipment. One such critical component is CFC fixtures and racks, which play an essential role in optimizing furnace throughput and ensuring the quality of treated products. But what makes CFC fixtures stand out, and why should they be part of your operation?

CFC stands for Carbon Fiber Reinforced Carbon, a material known for its excellent strength and durability at elevated temperatures. CFC fixtures and racks are designed to hold workpieces in place during heat treatment processes, whether in a furnace or oven. Unlike traditional metal fixtures, CFC fixtures are highly resistant to thermal shock and can withstand temperatures exceeding 2,000 °C.

This makes CFC racks ideal for industries where high temperatures are necessary, such as aerospace, automotive, and manufacturing of high-performance components. These fixtures and racks help maintain the shape and structure of the workpieces while ensuring efficient heat and gases distribution, ultimately contributing to better product quality.

The benefits of CFC fixtures in heat treatment are manifold. First, the material's high-temperature resistance allows it to perform consistently over extended periods in vacuum and inert gases, even at extreme temperatures. This leads to reduced wear and tear, meaning fewer replacements and less downtime for maintenance. Additionally, CFC racks maintain their shape under intense heat, which ensures that workpieces are consistently treated to the desired specifications.

Another key benefit is their ability to reduce cycle times. CFC fixtures can handle larger loads without losing structural integrity, which means more parts can be processed at once. The result is an increase in furnace throughput, which can potentially boost production rates by up to 100%, depending on the application. This can significantly improve your operational efficiency and reduce overall costs.

One of the standout features of CFC fixtures and racks is their longevity. The material’s resistance to thermal cycling and high heat environments means these fixtures last much longer than conventional ones. As a result, businesses save money on replacement costs and enjoy higher returns on their investment.

Additionally, CFC fixtures are lightweight yet strong, making them easier to handle and transport within the heat treatment facility. Their ability to withstand high thermal stress also means fewer issues with deformation, ensuring the integrity of the treated workpieces.

The high performance and longevity of CFC fixtures make them a superior choice compared to other materials, such as metals or ceramics. For any business looking to boost the efficiency of its heat treatment process while maintaining the highest standards of product quality, CFC fixtures and racks are a game changer.

Industries that demand precision and reliability in heat treatment can benefit greatly from CFC racks. In the aerospace industry, where parts often need to be subjected to extreme heat conditions, CFC fixtures ensure that components remain stable and maintain their integrity. This helps prevent costly defects and delays.

Similarly, in the automotive sector, heat treatment plays a vital role in manufacturing engine components, gears, and brakes. CFC fixtures ensure that these parts are treated uniformly, contributing to the durability and performance of the final products. With the increased load capacity and thermal resistance of CFC racks, manufacturers can increase output without sacrificing quality.

CFC fixtures and racks offer significant advantages for heat treatment applications. Their ability to withstand extreme temperatures, improve throughput, and reduce maintenance costs makes them a worthwhile investment for any heat treatment operation. By choosing CFC fixtures, businesses can achieve greater efficiency, higher product quality, and longer-lasting equipment. If you want to enhance the performance of your heat treatment processes and reduce operational costs, investing in CFC fixtures is the smart choice.

Ready to optimize your operations? Get in touch with High Temperature Concept today to learn more about how CFC fixtures can benefit your heat treatment process.